-

-

In this step we are constructing the frame.

-

You will need 4x T slot 20x20 L160, 9x T slot 20x20 L102, 20x Hidden corner connection slot 6.

-

Start by assembling using a 2mm Allen key.

-

Beware of the correct hidden corner connection orientation.

-

You can find the assembly diagram on the next step.

-

If you purchased square nuts that only fit into the slot from the end, be sure to insert them before assembling the frame with the hidden corners.

-

-

-

You should now have a complete frame.

-

Make sure you dont fasten the holding connectors for the extra L102 beam on one side.

-

Beware of the orientation (short side vs long side) of the hidden corners!

-

-

-

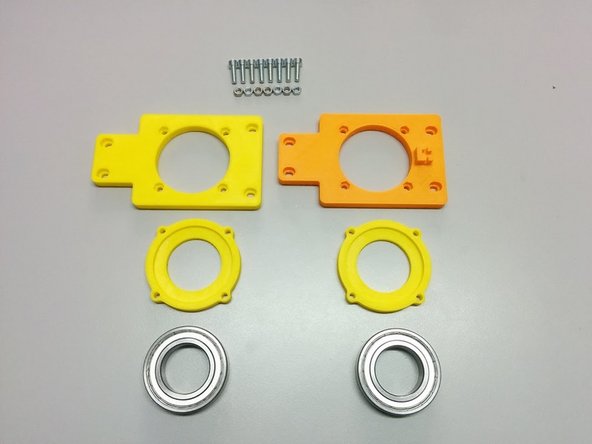

For this step you will need:

-

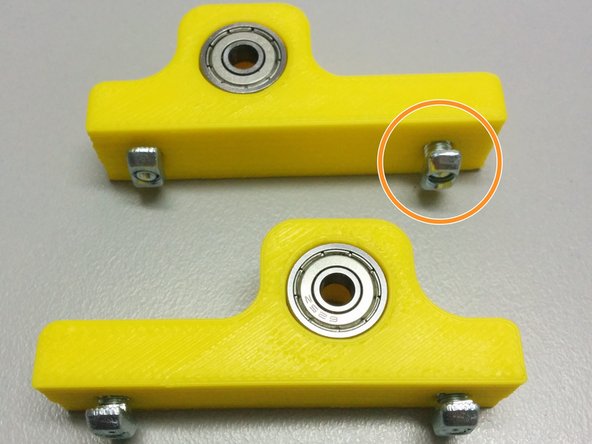

3D printed: Axis side with homing sensor, Axis side, 2x Ball bearing housing

-

8x M4-20 screws, 8x M4 nuts

-

2x Ball Bearing 6008ZZ (or appropriate for your tube diameter)

-

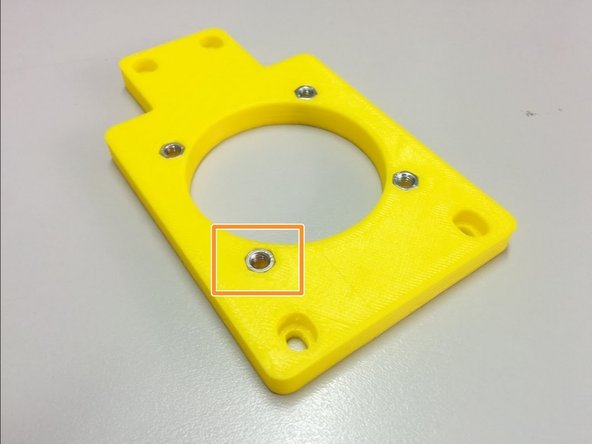

Insert the 8 nuts in the pockets of the axis sides.

-

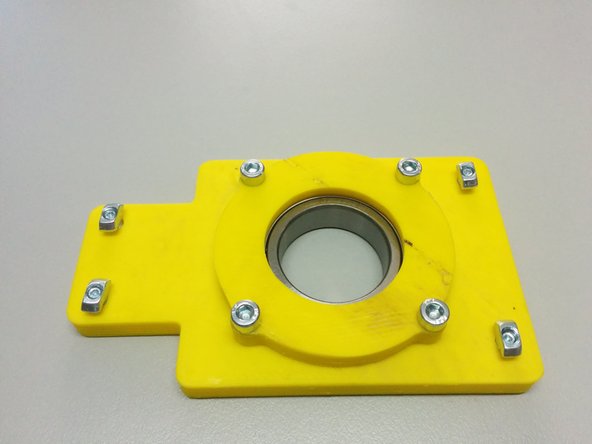

Attach the ball bearing housings on the back of each axis side and fasten it with M4-20 screws as shown.

-

-

-

Finally, place the ball bearings inside the pockets created.

-

-

-

In this step you will need:

-

1x side assembly (the one without the homing sensor holder)

-

4x M4 slot 6 nuts, 4x M4-10 bolts

-

Screw the M4-10 bolts through the side assembly as shown on the second picture and attach the M5 slot 6 nuts

-

Finally slide the whole piece inside the frame as shown (bottom side touching the frame) and secure it by screwing the 4 M4-10 bolts.

-

-

-

In this step you will need:

-

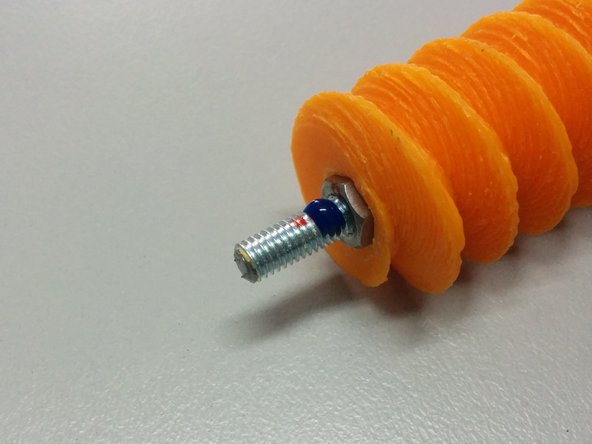

3D Printed: Worm gear

-

Thread lock glue

-

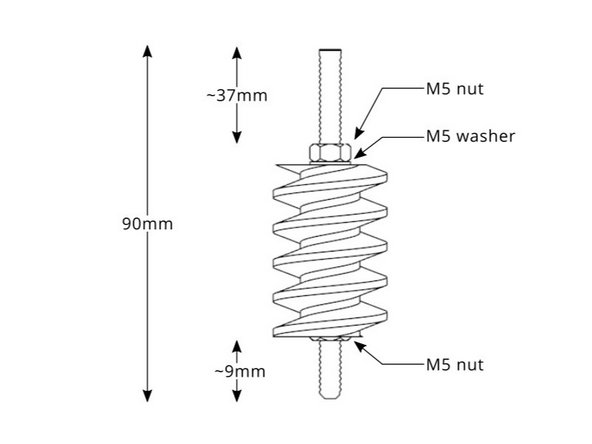

2x M5 nut, 1x M5 washer (wrong in the picture), 90mm M5 threaded rod

-

Apply glue as shown.

-

Follow the diagram for the dimensions.

-

-

-

In this step you will need:

-

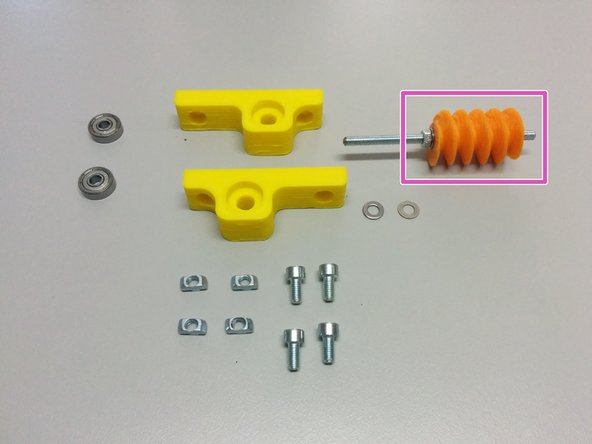

The previous worm gear assembly.

-

3D Printed: Worm mount

-

2 ball bearings 625ZZ

-

4x M4 nut slot 6, 4x M4-10 screws, 2x M4 washer.

-

Insert the ball bearings inside the pockets of the mounts. Then screw the bolts into the nuts slot6 as shown in the pic.

-

Finally slide the worm mounts in the slot 6 rails as shown. First the one without the gear assembly first, then the second with the gear assembly as shown.

-

Don't forget the washer between the ball bearings and the worm gear assembly.

-

-

-

In this step you will need:

-

The second axis side assembly (the one with the homing sensor holder)

-

2x M5 slot6 nuts, 2x M5-10 bolts

-

2x M4 slot6 nuts, 2x M4-20 bolts

-

The stepper motor mount.

-

Attach the bolts, slot 6 nuts and the stepper motor mount.

-

Finally attach the whole assembly to the frame as shown in the picture.

-

-

-

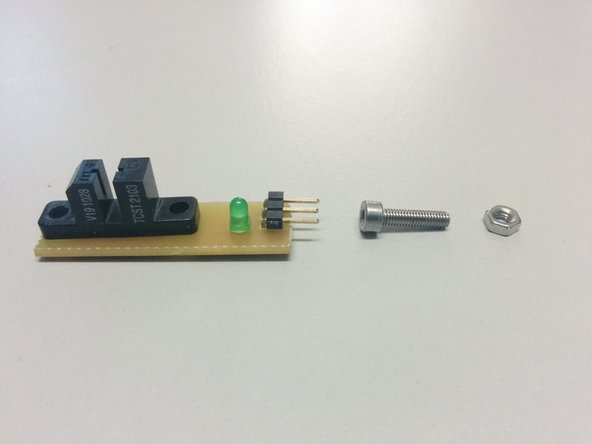

You will need:

-

The homing sensor electronic circuit

-

1x M3 nut, 1x M3-12 bolt, 1x M3 washer (not shown)

-

Mount the homing sensor on the axis mount as shown.

-

-

-

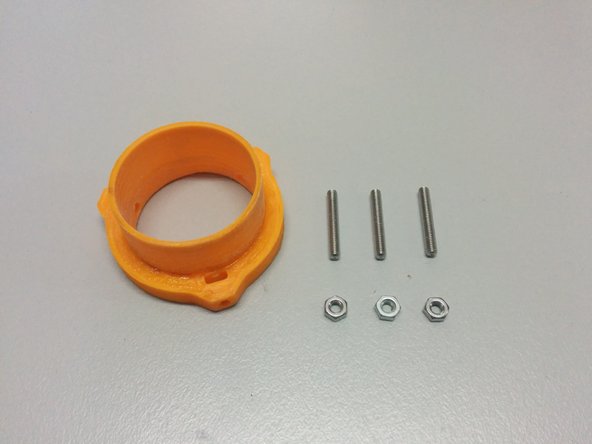

In this step you will need:

-

3D printed: Axis spacer collar

-

3x M3 nut, 3x M3-10 set screws

-

Insert the nuts in the pockets of 3d printed part, then screw the set screws as shown.

-

You may need to sand the final surface of your 3D printed part (check how it fits inside the side ball bearings.

-

-

-

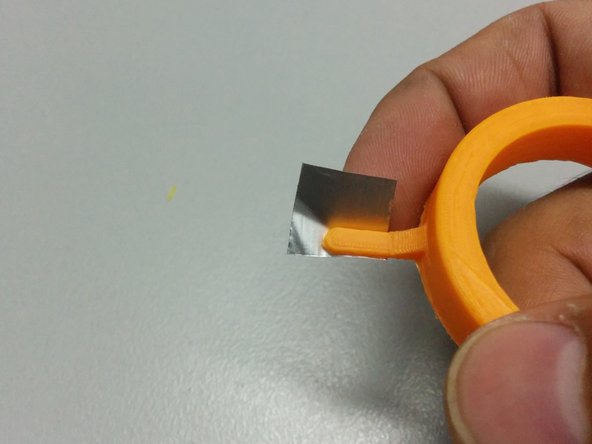

You will need:

-

The homing ring part

-

1x M3 nut, 1x M3-25 bolt.

-

One small piece of aluminum tape (or something that blocks the IR light)

-

-

-

Insert the M3 nut to axis gear part.

-

Pass the axis through:

-

Axis collar spacer

-

Homing ring

-

Axis gear

-

Warning: Make sure the hole is facing the top.

-

Axis spacer

-

-

-

Tighten the alen bolts on the axis spacer collar part.

-

Open a 3mm hole on the axis and tighten the M3-50.

-

Align the homing ring pin to the homing sensor and tighten the screw.

-

-

-

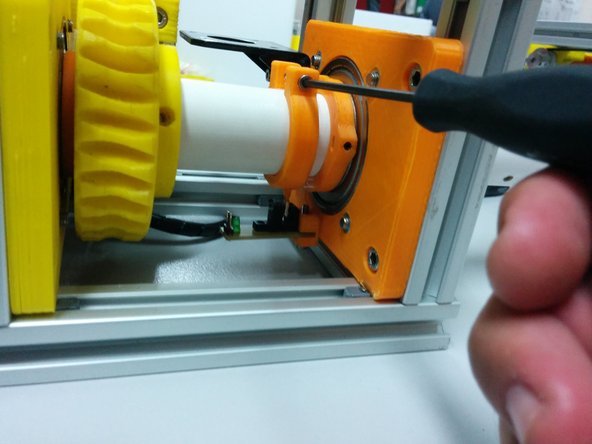

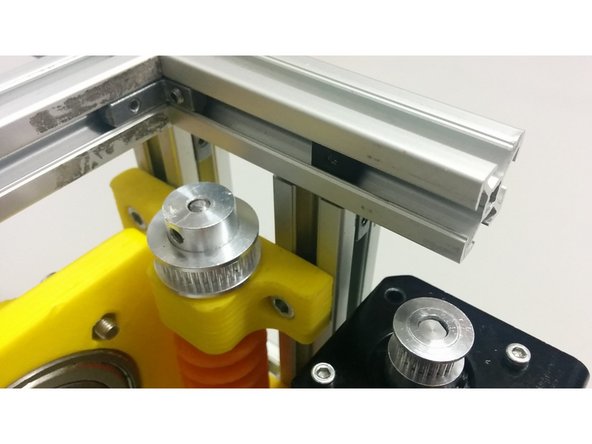

In this step you will need:

-

4x M3-6 /w washers

-

NEMA 17 stepper motor

-

GT2 pulley 20 tooth 5mm bore

-

Pass the pulley through the stepper motor shaft

-

Place the motor under the mount and tighten the screws.

-

-

-

In this step you will need:

-

3x M3 nuts

-

4x M3-6 Head cap screws

-

3x M3-12 Head cap screws

-

3D printed part motor_mount_flange

-

GT2 pulley 20 tooth 6mm bore

-

Bolt the motor on the flange

-

Insert the pulley over the motor shaft and bolt the flange, with the motor, on the motor base.

-

-

-

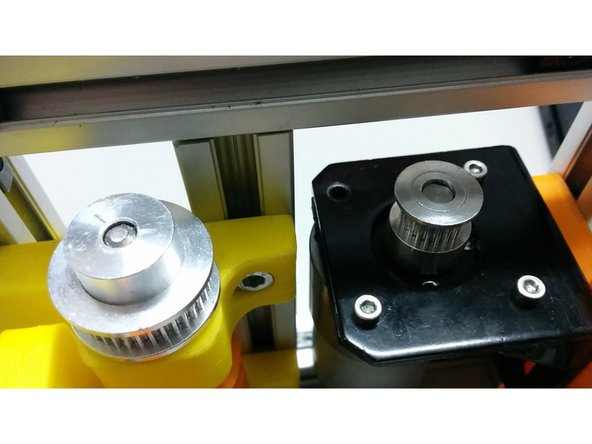

Loose the screws on the hidden corners in a way that stepper motor can slide towards the worm gear.

-

Place the the GT2 timing belt 158mm between the worm and motor pulleys.

-

Align the height of the pulleys and secure the pulley on the axis.

-

-

-

Slide the axis side to tighten the belt and secure the screws and hidden corners

-

Push the axis spacer collar onto the bearing and tighten the screws.

-

We are going to need:

-

40cm of wire for endstops

-

Connector for triple pin header

-

35 cm cable manager

-

Use cable manager to manage endstop and stepper motor cables.

-

Connect the endstop.

-

-

-

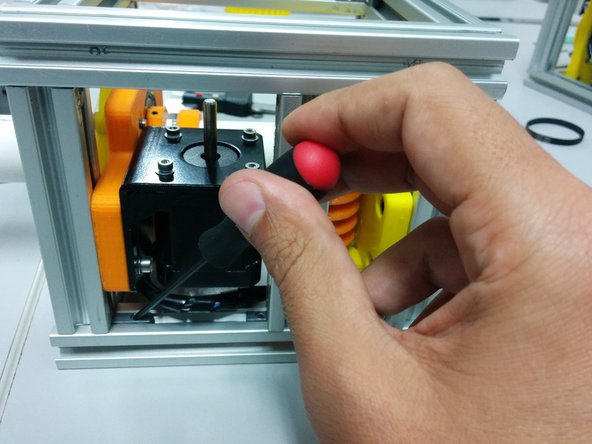

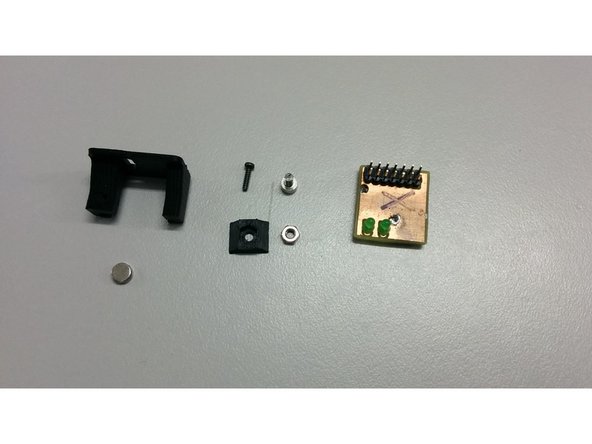

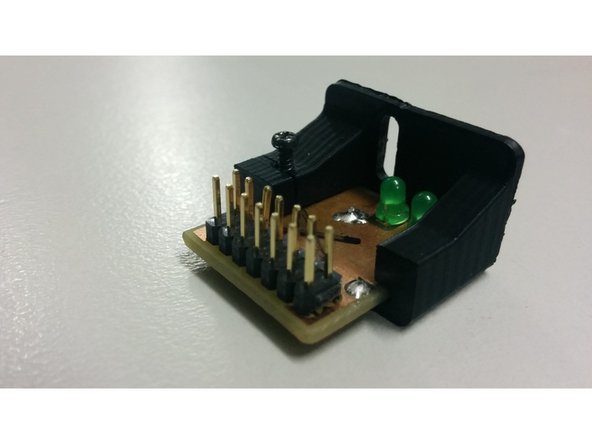

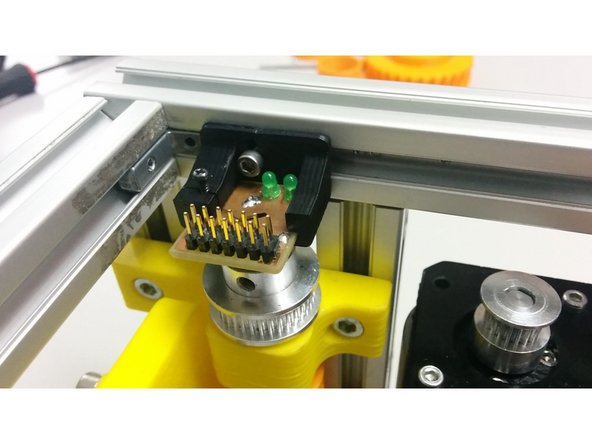

In this step you will need:

-

1x M3 nut

-

1x M3-6 Head cap screw

-

1x M2-6 Thread-Forming Screw

-

SatNOGS encoder board

-

1x D6x2.5 Neodymium Diametric Magnet

-

And 3D printed parts: M3_TSlot20_nut, encoder_holder

-

Place the nut into the 3D printed part and slide it into the aluminum profile

-

-

-

Slide The pcb into the 3D printed part and use the M2 screw to gently hold it in place

-

Using some cyanoacrylate glue, fix the magnet over the center of the pulley that is over the worm gear

-

Bolt and align the encoder over the magnet using the M3 screw

-

-

-

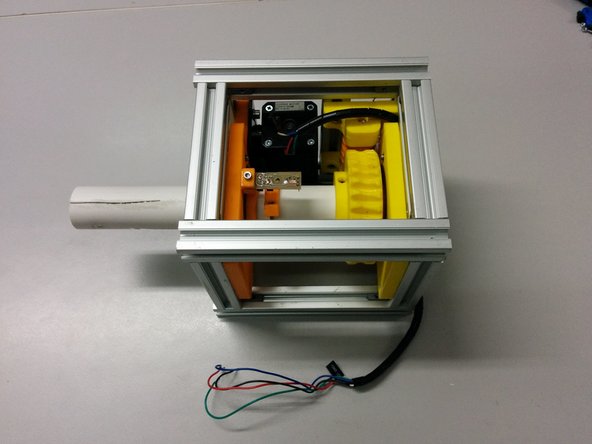

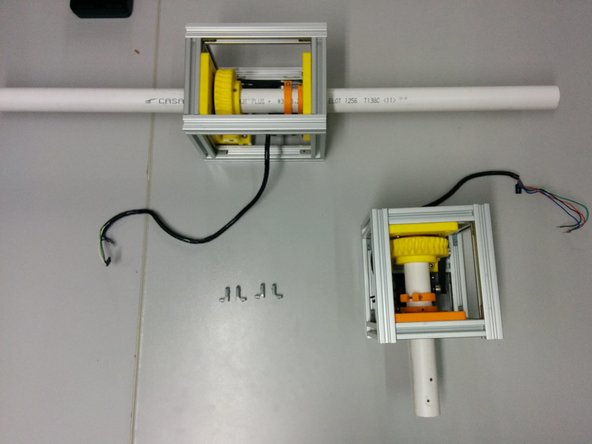

Assemble the elevation axis like the previous one. The only difference is that the length of t-slots that are parallel to the axis is 180mm and the timing belt is 202 mm.

-

Slide the hidden corners in the bottom side of the elevation axis.

-

Place the azimuth axis on top of the elevation in a way that the extension of the azimuth axis intersects with the elevation axis. Center it in the other direction.

-

-

-

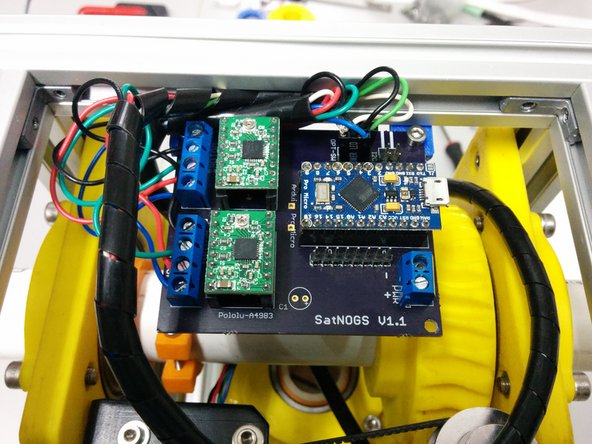

In this step you need

-

Assembled satnogs PCB controller

-

2x M5-14 screws, 2xM5 t-slot nuts

-

2x M3-10 screws, 2xM3 nuts

-

Make sure you are using the latest controller that can be found here https://github.com/satnogs/satnogs-rotat...

-

The controller depicted is an older version.

-